From seeds to the final product. We are an old-school brand that takes care of every single stage of the production process. We outsource nothing because we handle everything ourselves.

Some might say it’s not really necessary, and that’s true, but for us, it’s a matter of trust, transparency, and control – accepting responsibility, knowing the details, and having the power to change them.

Discover how we do it.

Our ingredients

If you want premium food, start with premium ingredients.

The ingredients we use come straight from our fields, local farmers, or trusted suppliers across Europe – only those who share our approach to food production. We don’t compromise and accept nothing less than full traceability.

Clean Label

We create our recipes using only ingredients familiar from home cooking and easily identifiable to anyone. We never use preservatives or artificial additives.

For us, this is a matter of transparency toward the consumer. Producing trustworthy food means we can't hide anything. What you see on the ingredient list is what you get. Period.

All in-house

We process all ingredients in-house. Once they arrive, they do not leave our facility until final delivery.

Production is conducted in accordance with TÜV FSSC 22000 certification, the gold standard in the food safety systems.

We cook

All of our meals are genuinely cooked before freeze-drying.

We celebrate nature not only when we spend time outdoors, but also by offering products that taste and look like it. With minimally processed, wholesome ingredients and real cooking, LYOFOOD meals bring to mind homemade food.

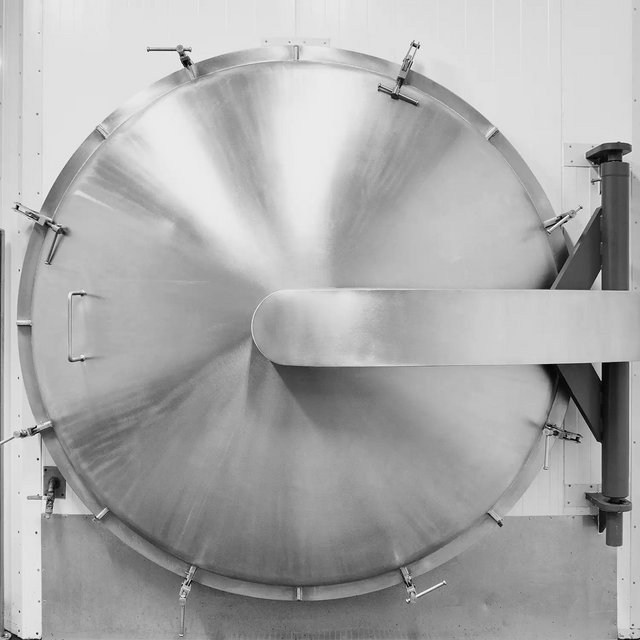

We freeze-dry

It's not black magic; it's pure physics.

Imagine a snow-covered meadow steaming at sunrise on a cold morning. Sublimation – this is what we recreate every day, but in special vacuum chambers. And there’s no better method for preserving the flavors, aroma, structure, and nutrients of fresh food, without any preservatives.

We test

We base the safety of our products on high-quality ingredients, strategic production schedules, and strict procedures, which include regular inspections in an external laboratory.

Allergen-free meals are packed on a dedicated line that eliminates the risk of cross-contamination. As an innovative company, we also operate our own laboratory, where we test each dish to ensure it is completely safe for the consumer.

We build

We not only freeze-dry but also engineer all our freeze-dryers. We know them like the back of our hand, down to the smallest screw.

Thanks to this technical expertise and our long-standing experience, we have been able to optimize our machinery and production processes, allowing us to use 30% less energy for the same tasks.

We pack

We design our own packaging and select the materials from which it is made, constantly seeking new solutions and striving to reduce material usage.

This can be quite frustrating in the age of greenwashing, but we do our best to make conscious decisions based on facts and figures

Renewable energy

In 2023, instead of starting a new investment, we purchased a former production facility and began its conversion.

Since January 2024, it has been powered entirely by renewable energy, as confirmed by the official certificate from PGE (Polish Energy Group).