It all started in the early 90s, when a Polish engineer working at a blood bank center came up with the idea of freeze-drying chives in his backyard.

“If it works with blood plasma, it should also work with vegetables, right?”

And it did.

So he quit his job at the blood bank and decided to freeze-dry food instead.

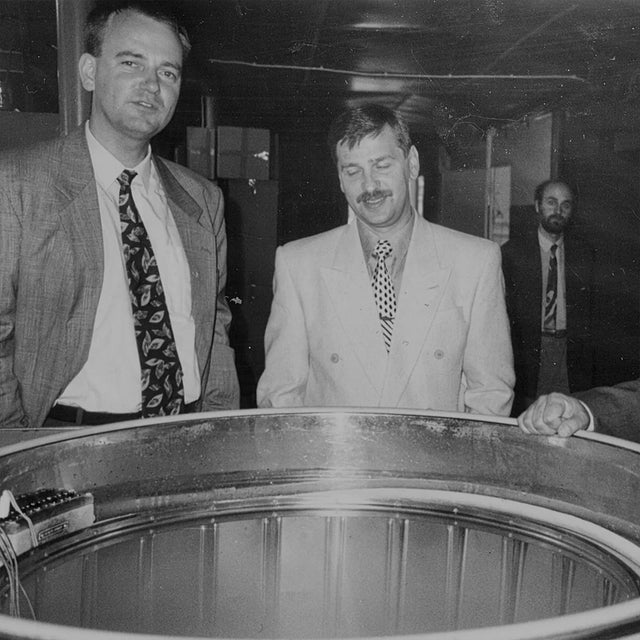

By then, freeze-drying had been used in military settings for several decades, and had emerged as an effective blood preservation technology, an alternative to fresh freezing, making it widely used by blood banks. Over the years of working at the station, Jerzy gained extensive knowledge of freeze-drying technology and the construction of freeze dryers.

Before leaving his job, he managed to buy back some old freeze-dryers and began modifying them to make them suitable for drying fresh food.

The golden age of blood plasma freeze-drying was long gone, and this advanced but expensive technology was being replaced by cheaper alternatives. While blood stations were upgrading to new equipment, an opportunity arose to salvage some of the freeze-dryers at scrap metal prices.

The company's first headquarters was located in a big chicken coop.

The immediate proximity of farmland was important, but what pleased the pragmatic engineer most was the fact that the chicken coop was already there = no need to build a factory, you just need to equip it.

The company’s first delivery car was the Fiat 126p, in which only the driver’s seat was left to obtain as much space as possible.

The car was manufactured in Poland under license from Italian Fiat. Due to its low price, it was probably the most popular car in the country the 1980s. Its very small size earned it the nickname “Maluch” ("the small one", "a small child"). The nickname became so popular that in 1997 it was accepted by the manufacturer as the official name of the car.

The first product on offer was freeze-dried chives cut by all family members and shipped to the Netherlands.

Once the tests on chives proved successful, it was time for onions and mushrooms. The high quality of the finished products attracted new customers, and it became clear that demand could soon exceed the company's capabilities.

From freeze-dried chives to complex expedition meals.

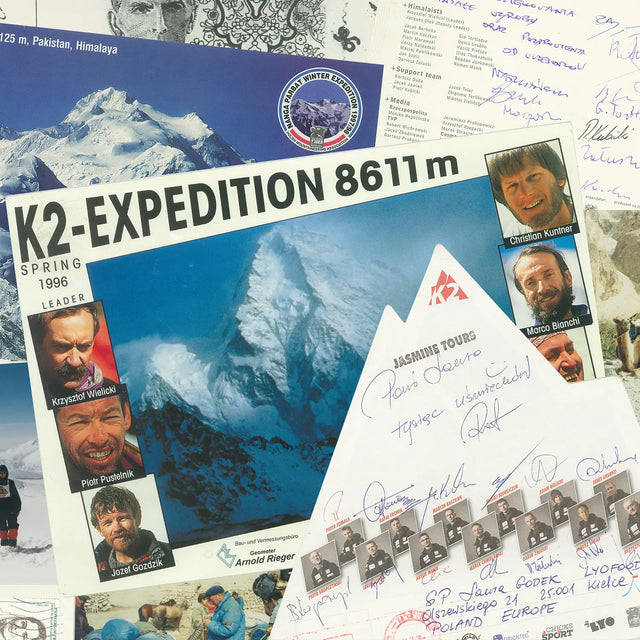

In the late 1990s, Polish travelers and mountaineers began approaching the company with requests for freeze-dried meals after having tried this type of expedition food during their trips abroad. Among them were stars of Polish Himalayan mountaineering, such as Krzysztof Wielicki. In the following years, the company provided these unique services in exchange for postcards, photos and interesting stories.

Here comes the second generation.

Over the years, the company grew, and so did the engineer's two daughters. Without any pressure or expectations, each of them went their own way, learning and gaining experience in completely different fields. Ultimately, however, the vibe, approach to business, and potential of their father's work made them want to become part of the story.

The missing link.

Laura and Wiola were full of ideas and energy, but something, or rather someone was missing… someone who could complete the whole and give these ideas the right form. When they met this guy, it became obvious that there was no need to look any further. The decision was made and Przemek joined the team.

It was 2010 and we started our journey to become LYOFOOD you know today.

Perfecting recipes, improving the production process, redesigning packaging, upgrading equipment, struggling on the market, making mistakes, making friends, being lucky, having fun... growing.